Teflon® Coating / Spray Coating

Teflon® Coating / Spray Coating

Do your parts present a unique coating challenge?

With over 60 years of experience and technical innovation, Thermech will transform your challenge into a success. We routinely apply extreme-service Teflon® coatings with unsurpassed quality, even to hard-to-coat parts.

Our coating selection expertise and application methods are second to none. We have achieved unheard of combinations of coating thickness, chemical resistance, temperature resistance, color, gloss or matte finish, abrasion resistance, hydrolytic stability, adhesion, electrical properties and custom masking. And we can coat parts that others can’t, such as the ID of extremely narrow medical hypotubes. All at reasonable price points and fast turnaround times.

Even when we use the same coating materials as other coating applicators, we apply the coatings using innovative, improved methods to achieve superior results. Some of the many ways that we improve upon standard coating practices:

-

•Consistent, superior surface preparation

-

•Additional processing steps between coats to improve appearance and intercoat adhesion

-

•Highly tailored thickness for each coat in multi-coat systems

-

•Customized numbers of primer-, mid- and topcoats according to the application requirements

-

•Custom drying and curing cycles

-

1.temperature ramp

-

2.time at maximum temperature

-

3.cooling speed

-

•Viscosity adjustments based on decades of experience

-

•Proprietary coating additives for enhanced properties

-

•Application-specific coating ingredient ratios

-

•Custom-made masking for superior precision and to improve masking speed to lower costs

We use a full range of coating materials and techniques to deliver the best solution for your project. We can handle even the toughest-to-coat surfaces or parts that are extremely small or very large.

We have developed techniques and processes that allow us to serve even the most quality-oriented industries such as aerospace and medical devices.

If none of our existing coating materials meets your requirements, we will compose a unique product for you as we have done for so many other customers. Our proprietary TECfluorcote fluoropolymer coatings and TECthermcote non-fluoropolymer coatings are unique solutions that complement standard industrial coatings.

Techniques / Capabilities

-

•Sizes up to 14 ft. x 8 ft. x 7 ft.

-

•Chemical and sandblast surface preparation

-

•On-site walk-in sandblasting room

-

•Comco MicroBlaster®

-

•High-precision masking

-

•Chain-on-edge and overhead conveyor lines

-

•More than 20 ovens for fast turnaround

-

•Custom methods

-

•Post-cure removal of metal discoloration

-

•Ultra-small inside-diameter coating (as small as 0.007” ID)

-

•Coating thickness accuracy to within 0.0002”

-

•High-powered microscopes

-

•Thickness testing (to test the dry film thickness of Teflon® coatings and powder coatings)

-

1.ElektroPhysik MiniTest 730 thickness gauge with FN 1.5 probe

-

✴Magnetic induction method to measure coating thickness up to 60 mils on ferrous substrates (except austenitic steel)

-

✴Eddy current method to measure coating thickness up to 27 mils on nonferrous substrates and austenitic steel

-

2.Micrometers

-

3.Pin gauge wires (for measuring the effective ID of hypotubes after coating)

Teflon® Coating / Spray Coating

Perfecting Surfaces Since 1949 •

(714) 533-3183 info@thermech.com

Spray application of liquid coatings from DuPont™ (Teflon®),

Whitford (Xylan®), Thermech (TECfluorcote and TECthermcote) and others

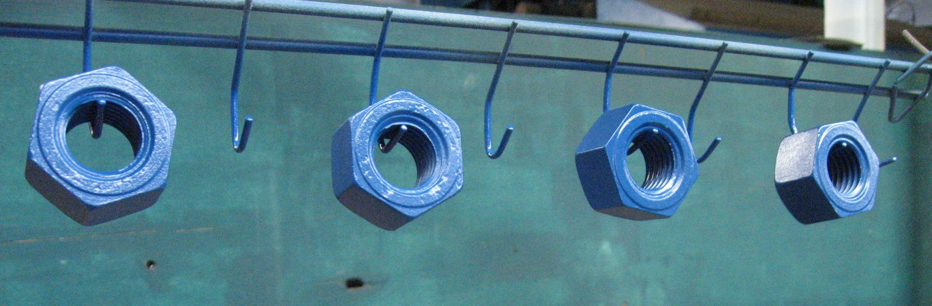

Coated for corrosion resistance and to prevent galling

Teflon® Coating / Spray Coating

Chemours Teflon Industrial Licensed Applicator

Whitford Licensed Applicator

PI / Vespel®

PPS / Ryton®

PES

FILLERS

THERMECH COATINGS

TECfluorcote

TECthermcote

DUPONT™ COATINGS

Teflon® PTFE

Teflon® FEP

Teflon® PFA

Teflon® One Coats

Teflon® PTFE/PFA Blends

WHITFORD® COATINGS

Xylan®

Xylan® XLR

Eclipse®

Dykor®

Xylar®

Halar® ECTFE

Teflon® ETFE

Teflon® FEP

Teflon® PFA

Ryton® PPS

PTFE Etching and Bonding

Home | Quality | Contact | About | History | Aerospace Coatings | Medical Device Coatings | Non-stick Commercial Bakery Coatings

Mold Release Coatings | Teflon® Coatings | Powder Coating | Compression Molding | Spray Coating Materials

Powder Coating Materials | Compression Molding Materials | Privacy Policy | Terms of Use | ©2010 Thermech Corporation. All Rights Reserved.

Teflon® is a registered trademark of E.I. du Pont de Nemours and Company used under license by Thermech Corporation. Only DuPont makes TEFLON®.

1773 West Lincoln Avenue, Building I • Anaheim, California 92801